How China cracked the code of Western industry Systemic decline

Last week, the American corporation Ford unveiled plans to reduce its manufacturing capacities in Europe. German automakers had made similar announcements earlier. European industry is withering before our eyes. The United States is facing significant challenges as well, especially in advanced sectors—from aerospace to microelectronics. Despite the long-standing semi-wartime situation, even the defence industry is struggling—recently, the British reported issues with missile production.

The entire industry of the collective West is in crisis, exacerbated by Western sanctions. Finding a way out is difficult—decades of outsourcing and shifting production to Asia have led to key development and manufacturing processes moving overseas. Reversing this trend is hard—neoliberal reforms have undermined the training systems in Western countries.

Decline of the Western automotive industry

Ford is cutting its workforce at factories in the EU, primarily in Germany, where there were already no surplus employees—only highly skilled personnel. Therefore, the reduction of about 4,000 jobs—around 14% of the American corporation's total workforce in Europe—is a significant move. However, even local automakers are leaving Europe. This fall, Volkswagen decided to close three factories in Germany. Workers at these factories even proposed foregoing a pay increase totalling 1.5 billion euros to persuade the company not to shut down the plants. Incidentally, real wages in Germany have already fallen by about a third since the start of the pandemic. In other words, people, in desperation, are offering their relatively wealthy employers their last pennies. Media outlets cite the decline in demand for electric vehicles and the loss of competition to Chinese counterparts as reasons for the troubles faced by Ford and Volkswagen.

Another crucial factor, less frequently discussed, is the EU's loss of access to cheap Russian energy resources and other raw materials, which has played a significant role in the current crisis facing European manufacturers (Germany's chemical industry, in particular, has been severely affected). However, the issues mentioned above only partially explain the problem, as similar trends are evident across the entire collective West. On November 8, Japanese automaker Nissan announced plans to cut 9,000 jobs and reduce global production capacity by 20%. The reasons cited include financial losses and declining sales in both China and the US. Moreover, Nissan is struggling to compete with Chinese car manufacturers.

Car sales in China have been on the rise recently—by 11.2% last month, with advanced electric vehicle sales growing by 56.7%. However, due to deteriorating relations between the US, the EU, and China, Western manufacturers are losing out to their Chinese counterparts without even engaging in competition. For instance, on October 4, under the collective pressure of German automakers, EU countries agreed to the European Commission's proposal to impose additional tariffs on Chinese cars, effectively closing off access to the much larger Chinese market for European products.

In contrast, Japanese automaker Toyota refused to participate in this collective self-destruction of Western carmakers. Instead, in October, Toyota reversed its strategy, deciding to increase production in China and grant more autonomy to its subsidiaries there for research and development. Unlike other Western manufacturers, which are scaling back production in China or pulling out altogether, Toyota is choosing to fight for the market of the future, rather than listening to the demands of an ageing global hegemon attempting to halt the course of history from across the ocean.

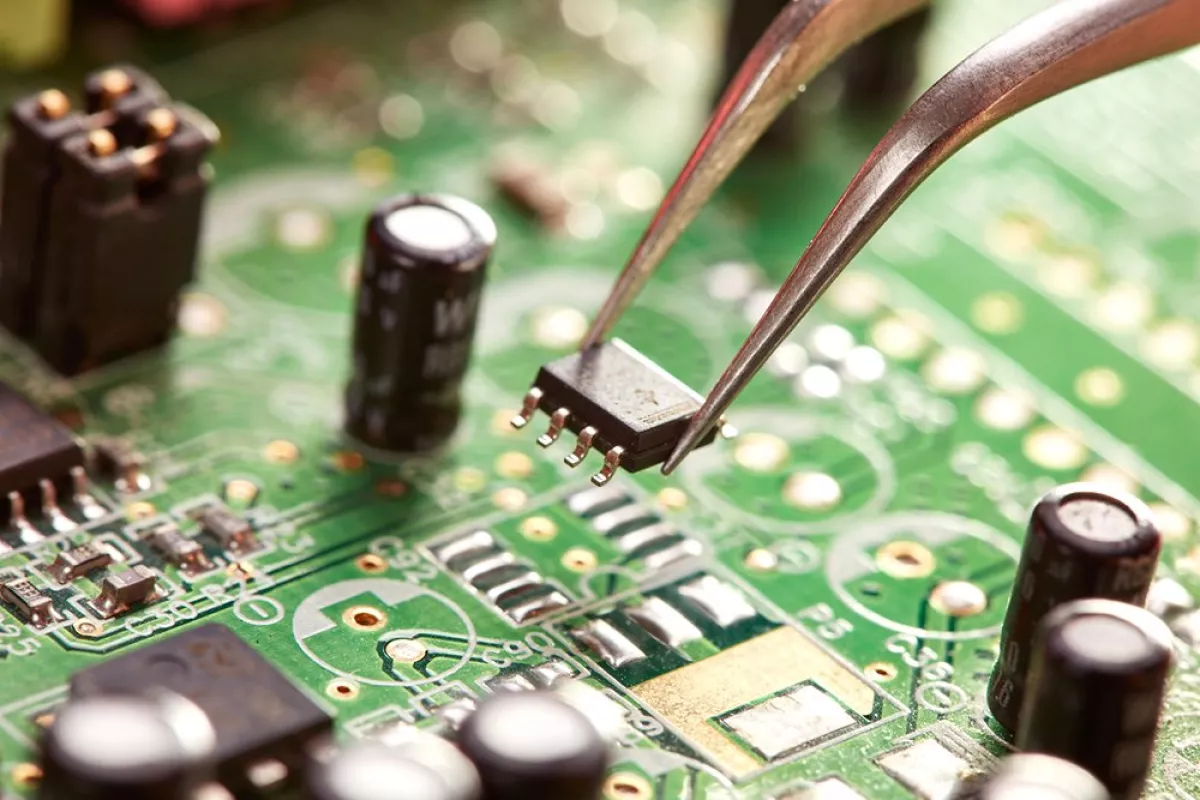

Billion-dollar aid can't save US microelectronics

The problems of the leading Western economies, of course, extend beyond the automotive industry. On November 14, leading American microelectronics company AMD announced a 4% reduction in its global workforce. One thousand employees are set to be laid off, supposedly to redirect resources toward the development of new AI chips. This explanation is questionable, as it means the company will lose some of the unique intellectual resources it has accumulated over the years. However, this is minor compared to the dramatic decline of the legendary American microprocessor maker Intel. At the end of September, the US government, despite being mired in massive debt, found $8.5 billion in emergency aid to help Intel survive. In March, the Biden administration already allocated nearly $20 billion in grants and loans to Intel for the development of domestic semiconductor production. At the same time, Intel also received billions from the EU to build state-of-the-art factories in Germany and Poland.

Nonetheless, by mid-year, Intel continued to sink and managed to lose more money in the second quarter than it had earned in profit the previous year. In August, the company announced an additional 15% workforce reduction. In September, it froze the construction of its new factories in the EU and began selling off property. By mid-September, Intel’s situation had become so dire that the threat of a takeover by US chipmaker Qualcomm loomed. To save Intel from this fate, Washington released new billions in aid.

A similarly bleak picture has emerged in the US aerospace industry. On October 24, Boeing informed investors that the company would run out of working capital by 2025. In an effort to resolve the crisis, on October 28, Boeing announced a plan to issue additional shares to raise $19 billion. Just days earlier, on October 20, it was revealed that Boeing would reduce production to combat its financial crisis. At the same time, the company will eliminate 10% of jobs within its own divisions, not to mention the many contractors who are already laying off employees in large numbers.

This crisis unfolded amid an ongoing strike by the corporation’s employees, but the strike is not the root cause of Boeing's problems, which began long before it.

For the past five years, Boeing has been rocked by a series of scandals, not just involving incidents like blatant violations of technological processes and quality control (for example, the mass installation of substandard parts), but also the mysterious deaths of whistleblowers who spoke out about these violations just before they were due to testify. Normally, Boeing would have successfully swept such "dirt" under the rug. However, five years ago, two brand-new Boeing airliners crashed in identical circumstances, killing hundreds of passengers. The cause was software, which was inexplicably and poorly designed—results of total outsourcing. Only after this tragedy did the media start paying close attention to the company, and reports began to surface about other incidents linked to Boeing, such as airplane doors falling off after takeoff.

Looking at the situation with two giants of American industry—Boeing and Intel—even the typically reserved Wall Street Journal has raised alarms about a "crisis." Both companies are facing enormous structural and technological problems, and they are staying afloat only thanks to extensive government aid. Without this support, they would have collapsed long ago—after all, in the past five years, the market value of these two firms has halved.

Sanctions vs markets

The position of Western industry has been undermined by sanctions and trade wars between the collective West and China, which have narrowed the markets available to Western producers. A clear example of this is the situation surrounding Samsung. In early September, it was revealed that the company from South Korea, a close ally of the United States, would urgently cut up to 30% of its overseas workforce by the end of the year. Last year, Samsung’s profits fell to a 15-year low, and the company is under immense pressure from competition not just from the American giant Apple, but from China's Huawei as well. However, Samsung is being hit not only by marketing miscalculations but also by actual and anticipated sanctions from the US and the collective West. In recent months, Chinese manufacturers have even made a record number of purchases of Samsung's high-capacity semiconductors, anticipating that the US will soon impose even stricter export restrictions.

The policy of cutting off producers from non-Western markets continues. Recently, it was revealed that the US plans to reduce exports of chips from several American manufacturers, such as Nvidia and AMD, to Arab countries! Officially, US authorities claim this is due to concerns about the re-export of these chips to China. However, in their efforts to combat a hypothetical and exaggerated risk, they are, in practice, narrowing the market for their own and other Western producers, while expanding it for non-Western competitors.

It is also important to note another reason— the consequences of state reforms in the West following the Cold War. With the need to compete with the USSR gone, the countries of the collective West turned to neoliberal reforms, which included cuts to science and education. When a new generation entered the labour market in Western countries, it quickly became evident that they were unable to tackle scientific and technological challenges. For a long time, this was solved through the "cheap and cheerful" method of brain drain from non-Western countries and outsourcing research and technology. However, the rise of anti-Russian and anti-Chinese paranoia has disrupted this approach. Even attempts to replace China or Russia with India have failed—the quality of work immediately drops in a catastrophic manner.

As a result, Western industry has reached a dead end, one created by policies that sought global hegemony. Now, we see daily examples of stagnation and degradation. Some of these are striking—such as the revelation that even the US space program, of strategic importance to Washington, has degraded to the point that it can no longer handle the simplest task: bringing astronauts back from a minimal (!) orbit. Remember, they were supposed to return in June, but due to a faulty capsule (manufactured by Boeing), their return has been delayed at least until March.

The shrinking of Western industry follows a simple model: Europeans are the first to degrade. For example, Intel has frozen its European projects but continues to implement its plans in the US. The Americans are cutting down European industry without hesitation, all in the interests of the US. Interestingly, this approach doesn't work with other members of the collective West: they are ready to fight for their survival, even against the Americans. A prime example of this is the behaviour of Japan's Toyota or the Chinese-Taiwanese company TSMC.

One final point: virtually all the industries and companies mentioned above are also involved in military contracts, which have been growing for years. This makes their degradation even more noteworthy. Interestingly, the problems with civilian products correlate with increasingly significant issues in the West’s defence industry as well. Despite efforts to paint a rosy picture in Brussels, the ongoing issue of the "million shells" that have yet to be delivered to Ukraine is not an isolated incident but a symptom of systemic decay. Similarly, the failures of new Western weapon systems to achieve miraculous results on the battlefield in Ukraine are clear signs of this decline. We have already seen such failures with systems like the Javelin anti-tank missile, Leopard and Challenger tanks, Patriot missile defence systems, F-16 jets, and ATACMS and Storm Shadow missiles...

In short, this is a systemic problem, not limited to individual companies, industries, or countries. The collective West, through its celebrated neoliberal transition, has built a socio-economic model that has led to the loss of its industrial base and technological lag.